Introduction

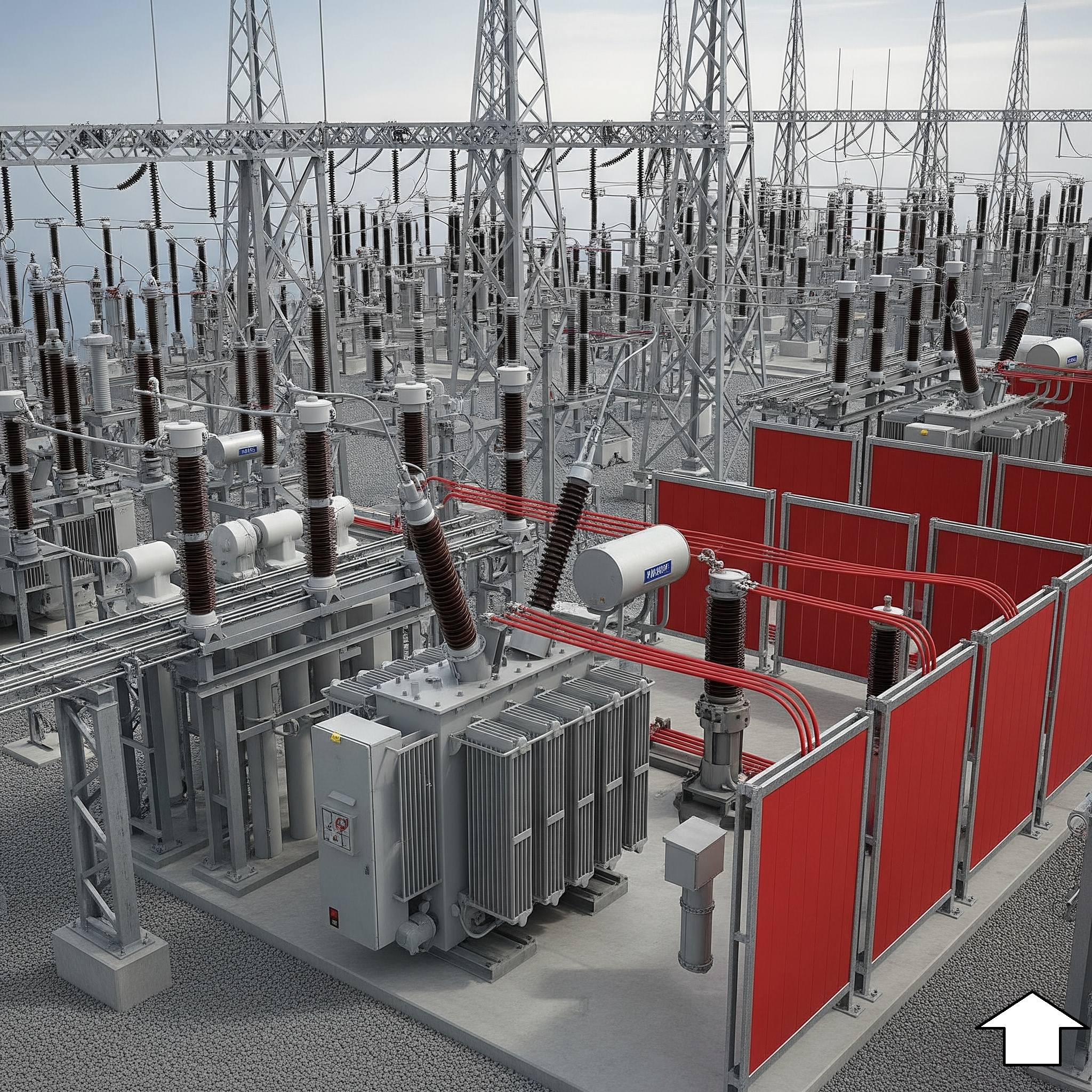

High Voltage (HV) and Extra High Voltage (EHV) substations form the backbone of South Africa’s power grid, supplying electricity to cities, industries, and homes. However, these critical hubs face significant fire risks. Ageing equipment, operational errors, and specific electrical hazards can lead to devastating power outages, extensive equipment damage, and serious safety threats to personnel and nearby communities.

That’s where Passive Fire Protection (PFP) comes in. Consider PFP as your substation’s silent guardian – always vigilant, working behind the scenes. Unlike active systems (such as sprinklers that require activation), PFP is integrated into the infrastructure and needs no power or manual intervention. This makes it highly effective, even during electrical faults. It complements active fire suppression systems to contain fires, minimise damage, and maintain operational continuity.

Adhering to South African regulations like SANS 10400-T and the Occupational Health and Safety (OHS) Act 85 of 1993, alongside international standards such as IEC 61936-1 and IEEE 979, is not merely about compliance. It’s a strategic decision for safety and resilience. Implementing robust PFP solutions delivers tangible economic benefits – reduced property damage, lower insurance premiums, minimal downtime, and enhanced safety for both staff and surrounding communities. Moreover, future-proofing substations involves adopting best practices in PFP installation, regular inspections, and proactive maintenance, potentially incorporating smart technology for real-time monitoring.

The Threat: Common Fire Hazards in HV/EHV Substations

Substations are complex environments, inherently susceptible to fires. Understanding these risks is the first step to ensuring their safety:

- Ageing Infrastructure & Poor Maintenance: Many substations in South Africa exceed their intended lifespan, with outdated hardware increasing fire risk. Poor maintenance and ageing electrical systems are major culprits, often leading to critical component failures that ignite fires.

- Oil-Filled Equipment: Transformers, vital to substation operation, contain large quantities of flammable insulating oil. A fault can provide both the spark and fuel for a fierce, rapidly spreading fire, classified as a Class B fire. Oil leaks also pose environmental risks, complicating fire control.

- Electrical Faults: High-voltage cables are prone to ignition from electrical faults. Over time, insulation degradation can cause overheating, leading to potential fires.

- Lightning Strikes: A common external threat, lightning can directly damage equipment like transformers, resulting in extensive fire damage.

- Poor Housekeeping: Visible weeds, existing oil leaks, and loose electrical components significantly contribute to fire hazards. A study found that 93% of 132 kV electric distribution substations in South Africa scored below 75% on housekeeping compliance.

- Inadequate Fencing, Vandalism, and Theft: Poor fencing increases security risks, making substations vulnerable to vandalism and theft, which can cause hardware failures and elevate fire risk.

- Operational Overloads: Grid instability, sometimes due to renewable energy integration, can lead to operational overloads, contributing to transformer fires.

These incidents have profound socioeconomic impacts, particularly in South Africa, where load shedding is a persistent challenge. Protecting substations with PFP is not just about preserving equipment; it’s about safeguarding national economic stability, public safety, and social wellbeing.

Consider the Boksburg Substation explosion in October 2019. The explosion was so powerful it shattered windows half a kilometre away and reduced steel-reinforced concrete to ashes, causing days of power outages. The total cost, including lost productivity and repairs, exceeded R30 million. This was attributed to neglected maintenance. More recently, a series of substation fires in Tshwane (Zwartkop, Waltloo, Brakfontein, and Mooikloof) raised concerns about potential sabotage, neglect, and absent fire prevention systems, leading to prolonged outages. PFP, being built-in and passive, is more resistant to deliberate interference or neglect, making it a robust defence.

Why Passive Fire Protection is Critical for HV/EHV Substations

PFP systems are non-mechanical solutions that contain fires and smoke without requiring external power or manual activation. In substations, where transformers, switchgear, and cables are at risk, PFP plays a vital role in minimising fire spread, preserving structural integrity, and ensuring safe evacuation and operational continuity.

1. Containing Fires with Penetration Seals

Cables, conduits, and pipes create openings in substation walls and floors. These penetrations act as pathways for fire, smoke, and toxic gases to spread rapidly. Penetration seals, or firestops, use materials like silicone-based sealants or intumescent compounds to fill these gaps. When exposed to heat, they swell to form a fire-resistant char or maintain integrity, effectively sealing the opening. Tested to standards like EN 1366-3 or ASTM E814/UL 1479, these seals prevent fire spread for specified periods. Firestopping is essential for openings created by electrical services, including cables, conduits, and busbars. For instance, a 2022 fire in a Pretoria substation was contained by firestops, limiting damage to a single compartment and preventing a wider outage.

2. Protecting Cables with Fire-Resistant Coatings

High-voltage cables are highly susceptible to ignition from electrical faults or external fires. Intumescent or ablative coatings are applied to cable surfaces. At temperatures above 200°C, intumescent coatings swell, forming a thick, insulating char layer, expanding up to 800% of their original thickness. This char insulates cables, maintaining circuit integrity during a fire, reducing downtime, and preserving power supply. Ablative coatings absorb heat through a chemical process, protecting the cable. Compliant with standards like UL 1709, IEEE 383, and IEC 60332-3A, these coatings ensure functionality. Modern formulations are non-toxic and aesthetically versatile, blending seamlessly while enhancing safety.

3. Compartmentalising for Safety and Continuity

Fire-resistant walls, floors, and doors divide large substation areas into smaller fire compartments. This strategy contains fires within their origin, protecting adjacent assets like transformers and control rooms. Materials like refractory concrete, which retains strength at temperatures up to 1,300°C, are preferred for transformer fire walls. These barriers, designed to withstand intense heat for 3–4 hours (per standards like Ausgrid’s NS171), ensure safe evacuation pathways and maintain operational continuity. Fire doors, self-closing and equipped with expanding seals, create barriers against flames and smoke. Fire and smoke dampers in HVAC systems prevent spread through ductwork. SANS 10400-T mandates specific fire ratings (e.g., 120 minutes) for high-risk areas. In a 2023 Durban substation project, Lionize Group’s fire walls prevented fire spread, saving an estimated R10 million in equipment costs.

4. Preserving Structural Integrity

Steel structures in substations can lose load-bearing capacity at 550°C without protection. Intumescent coatings on structural steel expand to insulate, maintaining stability up to 1,200°C. A 2024 Eskom study showed that PFP-coated structures reduced repair costs by 35% post-fire. Other materials, like fireproofing cladding, mineral wool wraps, and endothermic materials (e.g., gypsum-based plasters), further enhance protection.

5. Dedicated Transformer Fire Barriers

Oil-filled transformers pose a significant fire risk due to their combustible oil content. Transformer fire barriers isolate transformers from adjacent equipment and structures. These barriers must extend at least 0.31 metres above the transformer casing and oil conservator tank and 0.61 metres beyond the width of the transformer and cooling radiators. Traditional concrete loses strength above 650°C, inadequate for hydrocarbon oil fires reaching 960–1,200°C. Barriers must be rated for four-hour, high-heat-flux exposure at 1,200°C. Lionize Group uses advanced materials to meet these requirements, ensuring robust protection.

The Synergy: Passive and Active Fire Protection Working Together

While PFP provides a robust, always-on defence, it works best alongside active fire protection systems for a comprehensive strategy:

- PFP contains and compartmentalises, slowing fire spread and limiting damage to a specific area, buying critical time.

- Active systems (e.g., water mist, CO2, or foam suppression systems) respond to the contained fire. PFP ensures the fire remains manageable, preventing it from overwhelming suppression systems. It’s vital if active systems fail due to power outages.

For example, a transformer fire barrier (PFP) contains an oil fire, allowing a water spray system (active) to cool and extinguish flames efficiently, protecting adjacent equipment.

Economic and Operational Advantages of PFP

Investing in PFP is a strategic financial decision with significant benefits:

- Minimised Damage and Repair Costs: PFP reduces equipment damage, lowering repair costs. The Boksburg Substation explosion (2019) incurred costs exceeding R30 million, which PFP could have mitigated.

- Reduced Downtime and Revenue Loss: By maintaining operational continuity, PFP minimises outages and economic disruption.

- Lower Insurance Premiums: Comprehensive PFP reduces risk, leading to preferential insurance rates.

- Enhanced Safety: PFP slows fire and smoke spread, ensuring safer evacuation and safer conditions for emergency responders.

- Reputation Protection: Minimising outages preserves public trust and utility reputation.

- Regulatory Compliance: Avoids penalties and legal issues by meeting fire safety standards.

The initial investment in PFP is far outweighed by the potential costs of a major fire, making it a cost-effective measure for economic stability and safety.

Regulatory Landscape: Standards in South Africa

Compliance with fire safety standards is paramount for HV/EHV substations:

- SANS 10400-T (National Building Regulations – Part T: Fire Protection): Specifies fire resistance ratings (e.g., 30–120 minutes) for building elements in substations.

- IEC 61936-1: Provides guidelines for fire safety in high-voltage installations.

- Eskom Standard TST41-224: Details PFP requirements for oil-filled equipment in high-voltage yards.

- Occupational Health and Safety Act (OHS Act) 85 of 1993: Mandates a safe working environment, including fire protection measures.

- SANS 428 & SANS 10177 Series: Govern fire performance and testing of construction materials.

- EN 1366-3, UL 1709, ASTM E814/UL 1479: International standards for testing PFP materials.

Compliance ensures safety and mitigates legal and financial risks.

Best Practices: Installation, Inspection, and Maintenance of PFP

PFP effectiveness depends on proper installation and maintenance:

- Expert Installation: Certified professionals must install PFP, ensuring precision for complex electrical penetrations.

- Regular Inspections: Annual inspections check for damage or degradation in seals, coatings, and barriers.

- Manufacturer Specifications: Adherence to guidelines ensures performance and warranty validity.

- Documentation: Comprehensive records track installations, inspections, and repairs for compliance.

- Post-Modification Review: New installations or modifications require PFP reinstatement.

- Maintenance Integration: Incorporate PFP checks into broader maintenance schedules.

Recent Advancements in Passive Fire Protection

Innovations enhance PFP effectiveness:

- Enhanced Intumescent Coatings: Nanotechnology improves durability and adhesion, with non-toxic options.

- Advanced Firestop Sealants: Modular systems simplify installation and maintenance.

- Fibre-Reinforced Composites: Lightweight, high-thermal-resistance materials for barriers.

- Smart PFP Solutions: IoT-enabled systems monitor temperature and integrity in real time.

- Modular Fire Barriers: Prefabricated units for easy, customised installation.

Case Studies: PFP in Action (Success Stories)

International examples highlight PFP’s impact:

- Heathrow Airport Substation Blackout (March 2025): Firewalls contained a fire, limiting losses to approximately £3.7 million, preventing a larger incident.

- Bungama Substation Fire (Australia, March 2024): Transformer fire barriers contained an oil fire, enabling quick service restoration.

Conclusion

Passive fire protection is an essential investment for HV/EHV substations, providing a vigilant defence to contain fires, protect equipment, and ensure continuity. Lionize Group’s tailored solutions, compliant with SANS 10400-T, Eskom TST41-224, IEC 61936-1, and IEEE 979, safeguard South Africa’s power infrastructure. Don’t leave your substation vulnerable – act now to protect your assets.

Call to Action: Protect your vital assets today. Contact Lionize Group for a free consultation on PFP solutions customised for your substation. Email info@lionize.co.za or call +27 (0) 10 880 3956.